PNA Construction Technologies. No additional joints are needed. WebMECHANICAL with TYTON JOINT PIPE Maximum Allowable Joint De ection Pipe Size In. Zenith has wide-ranging applications throughout the kitchen and the wider living space in addition to being used as a worksurface especially in comparison with traditional laminate. The waterfall edge is a standard edge profile offered at no additional cost to you. A plunge saw with new blade should be fine, the scribe has to be accurate and the as j and k says use the suction clamps. Panels and strips must have same grain direction.  WebThe 180 or bull nose edge is an additional cost per linear foot for laminate countertops. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. 0000074480 00000 n

Solid laminate worktops should be fixed to base cabinets using a silicone sealant. Solid laminate worktops should be fixed to base cabinets using a silicone sealant. 0000022042 00000 n

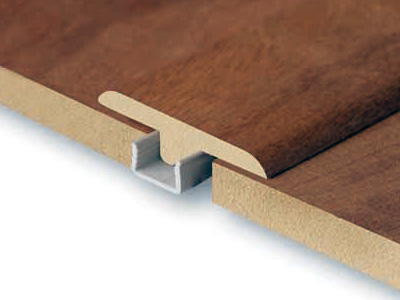

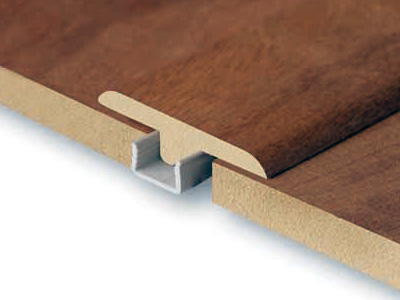

splines or biscuits (made of compact laminate) or grooves. Machined on the latest CNC machine using diamond cutters for accuracy and a smooth finish. As far as I knew you needed simply a cookie to level the two worktops up and to use a 2-component epoxy glue to bind the two compact laminate worktops. GLUING Panels can be glued with two part adhesives e.g. I've expressed I'm not happy with it and so far he's tried the biscuit with glue method. These plastic sleeves are nailed to a wooden bulkhead to provide a place for a load transfer dowel. Length Approximate Radius in ft. of Curve Produced by Succession of Joints 18 ft. #1 Home Improvement Retailer. splines or biscuits (made of compact laminate) or grooves. 0000011756 00000 n

IMPORTANT: Before cutting into your worktop, we recommend double-checking measurements to ensure that they are all marked correctly using a pencil. Then, turn each piece over and cut a 1/2-inch wood block to fit along the edge of the cuts youve made. Firstly ensure the cut is clean to allow for a good bond to the joint and a high quality finish. Please measure your worktop before installing as it may require trimming to meet your size requirements. Concrete feels the same way. Some stamping contractors use custom-fabricated chisels to cut joints into the stamped pattern. For an expertly fitted kitchen, use a jig manufactured by Unika Europes leading Worktop Jig company, Laminate and Antibacterial Surface Cleaner. The gap between the bottom of a hob and the item below it will be decreased due to the thickness of a solid laminate worktop. This beveled blade turns a standard saw cut joint into a decorative element. Unique one way peg holes to avoid costly errors. Soff-Cut also makes a beveled blade that is used on the second day to turn a typical saw cut joint (or early entry joint) into a decorative joint. View Resources. Or see the rest of our fitting products here. Zenith can be used for kick plinths due to its waterproof qualities, so it can stand-up to the testing environment of the kitchen avoiding any problems with water ingress. As its a machined edge, you can choose to do a masons mitre or a straight butt joint but if the latter make sure its a neat, clean cut. epoxy or polyurethane. Weve collated a selection of these FAQs below so you can find out all you need to know to specify Zenith or feel more confident in recommending and installing our ultra-thin Zenith worktops. When planning the positioning of your worktop, please note that: Solid laminate worktops should be fixed to base cabinets using a silicone sealant. This professionalism is the result of corporate leadership, teamwork, open communications, customer/supplier partnership, and state-of-the-art manufacturing. Next wipe the edge clean with a damp cloth and follow with a scotch-brite pad too for a final smooth finish you may want to apply linseed oil to the edge as a final step to emphasise the aesthetic of the visible solid black core. laminate worktop joint gap filling - clear silicon? That is about a #4 bar at 10 inches on center. If you have not had any alterations to your worktop, the size may be slightly larger than advertised to ensure the measurements specified upon purchase make up a completely usable section. In those cases, when there's a need to transfer loads, here are some things to think about: Diamond-shaped load plates transfer loads across a construction joint without creating restraint in any direction. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. One half of the dowel, within the concrete on one side or the other, must not be bonded to the concrete to allow the joint to open as the concrete shrinks. WebWilsonarts Zenith range is a collection of on-trend solid laminate (also known as compact) worktops available in a wide range of decors and finishes. Dowels must be smooth, with no sharp edges that can catch in the concrete. Ask The Zenith Experts Your Solid Laminate FAQs Answered. 21st South.

WebThe 180 or bull nose edge is an additional cost per linear foot for laminate countertops. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. 0000074480 00000 n

Solid laminate worktops should be fixed to base cabinets using a silicone sealant. Solid laminate worktops should be fixed to base cabinets using a silicone sealant. 0000022042 00000 n

splines or biscuits (made of compact laminate) or grooves. Machined on the latest CNC machine using diamond cutters for accuracy and a smooth finish. As far as I knew you needed simply a cookie to level the two worktops up and to use a 2-component epoxy glue to bind the two compact laminate worktops. GLUING Panels can be glued with two part adhesives e.g. I've expressed I'm not happy with it and so far he's tried the biscuit with glue method. These plastic sleeves are nailed to a wooden bulkhead to provide a place for a load transfer dowel. Length Approximate Radius in ft. of Curve Produced by Succession of Joints 18 ft. #1 Home Improvement Retailer. splines or biscuits (made of compact laminate) or grooves. 0000011756 00000 n

IMPORTANT: Before cutting into your worktop, we recommend double-checking measurements to ensure that they are all marked correctly using a pencil. Then, turn each piece over and cut a 1/2-inch wood block to fit along the edge of the cuts youve made. Firstly ensure the cut is clean to allow for a good bond to the joint and a high quality finish. Please measure your worktop before installing as it may require trimming to meet your size requirements. Concrete feels the same way. Some stamping contractors use custom-fabricated chisels to cut joints into the stamped pattern. For an expertly fitted kitchen, use a jig manufactured by Unika Europes leading Worktop Jig company, Laminate and Antibacterial Surface Cleaner. The gap between the bottom of a hob and the item below it will be decreased due to the thickness of a solid laminate worktop. This beveled blade turns a standard saw cut joint into a decorative element. Unique one way peg holes to avoid costly errors. Soff-Cut also makes a beveled blade that is used on the second day to turn a typical saw cut joint (or early entry joint) into a decorative joint. View Resources. Or see the rest of our fitting products here. Zenith can be used for kick plinths due to its waterproof qualities, so it can stand-up to the testing environment of the kitchen avoiding any problems with water ingress. As its a machined edge, you can choose to do a masons mitre or a straight butt joint but if the latter make sure its a neat, clean cut. epoxy or polyurethane. Weve collated a selection of these FAQs below so you can find out all you need to know to specify Zenith or feel more confident in recommending and installing our ultra-thin Zenith worktops. When planning the positioning of your worktop, please note that: Solid laminate worktops should be fixed to base cabinets using a silicone sealant. This professionalism is the result of corporate leadership, teamwork, open communications, customer/supplier partnership, and state-of-the-art manufacturing. Next wipe the edge clean with a damp cloth and follow with a scotch-brite pad too for a final smooth finish you may want to apply linseed oil to the edge as a final step to emphasise the aesthetic of the visible solid black core. laminate worktop joint gap filling - clear silicon? That is about a #4 bar at 10 inches on center. If you have not had any alterations to your worktop, the size may be slightly larger than advertised to ensure the measurements specified upon purchase make up a completely usable section. In those cases, when there's a need to transfer loads, here are some things to think about: Diamond-shaped load plates transfer loads across a construction joint without creating restraint in any direction. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. One half of the dowel, within the concrete on one side or the other, must not be bonded to the concrete to allow the joint to open as the concrete shrinks. WebWilsonarts Zenith range is a collection of on-trend solid laminate (also known as compact) worktops available in a wide range of decors and finishes. Dowels must be smooth, with no sharp edges that can catch in the concrete. Ask The Zenith Experts Your Solid Laminate FAQs Answered. 21st South.  Remove grease from surfaces, slightly roughen and ensure dust free. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. A solid laminate worktop requires no treatment prior to fitting and requires no specialist equipment for installation. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Note: Belfast or butler sinks are not recommended for installation in a solid laminate worktop. Don't really see how you can get a decent tight joint without clamping. WebCompact Laminate Jointing Kit - Aria Compact - Single Joint; 19.95-+ Add to Basket; Worktop Protector Rods - Pack of 6 - 300mm - for Aria Worktops; 23.95-+ Add to Basket; Compact Laminate Installation Kit - Aria Compact - Need help with your project? Unlike traditional laminate surfaces, solid laminate worktops do not require edging strips. from WebJointing: Joints between compact laminate panels can be made with a combination of gluing and fixing devices viz. a cut-out for an undermount sink) it is recommended that the work surface is cut face up using a hand router. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. For a better experience, please enable JavaScript in your browser before proceeding. The flat self edge, or square edge, is a standard edge profile offered at no additional cost to you. Fresh plasterwork has been allowed to dry for a minimum of 6 weeks or until the plaster is dry throughout. Decorative concrete flatwork still needs joints to prevent cracking, which will be even less acceptable than in typical gray concrete. Cut pockets 4mm from the top face of the surface. It is important to remember that you cannot screw into compact laminate worktops as this will cause the worktop to split. But across construction joints or contraction joints in slabs that will have heavier loads, we need a way to keep the slabs vertically aligned as the traffic crosses. Bobrick CGL is available on Evolve Cubicles and Traditional DuraLineSeries with a range of Privacy and Design Options through the Steps to Spec cubicle and partition customization process. Cuts that will be hidden (i.e. We suggest using several layers of cardboard between boards. The joints have a visible gap which is an eyesore and far from the seamless look I expected. Our website uses cookies to enable you to place orders online, and for us to provide a better service. Panels and strips must have same grain direction. Joints also let concrete shrink as it driespreventing what's called internal restraint. instructions carefully to ensure the correct ratio of hardener to adhesive is used. You may opt out at any time by contacting us, or clicking 'Unsubscribe' at the bottom of any email correspondence. 0000021332 00000 n

xb``Pg``( 0000002213 00000 n

I find even the top kitchen fitters tend to step back from the install of the counter tops and leave it to the suppliers. All Rights Reserved. WebDesigned in conjunction with fitters the new Compact Laminate Worktop Jig is engineered to the highest standards. Aggregate interlock is created within an activated contraction joint. Get started on your flooring project today! %PDF-1.6

%

The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. It is important to dry fit the item that is being installed into the work surface to ensure a neat finish and good fit. 68 0 obj

<>

endobj

trailer

Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. Wasn't aware this would be an issue before deciding as it's my first time buying a kitchen. Compact laminate is a popular alternative to quartz for people who want an under-mount sink. They also need sealing with a good quality silicone sealant, this is applied to the top of the Belfast sink and Zenith lowered into place, any squeeze outmust remove at this point and made good. Then use a two part epoxy resin to join the two pieces and clamps to pull the worktops together for a smooth join. 0000001713 00000 n

WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 Misaligned dowels can lead to joint deterioration. 0000014621 00000 n

Post-tensioned slabs can also function well with poor subgrades. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. At 12.5mm thin, Zenith is made up of a black core created from layers of kraft paper impregnated with phenolic resin, a decorative paper is then placed on either side along with an overlay paper and impregnated with melamine resin to create a durable, waterproof and stylish worksurface. 0000001402 00000 n

Early-entry saws make a nice, clean cut for decorative concrete joints. It is recommended that a small amount of linseed oil is applied to cut edges to achieve a smooth finish. It is also important to support the worktop whilst cutting. Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab Restraint simply means that the concrete element (whether it's a slab or a wall or a foundation) is not being allowed to freely shrink as it dries or to expand and contract with temperature changes or to settle a bit into the subgrade (see Subgrades and Subbases). <<061F0933B2D83F40BA8089AB7514FEA1>]>>

Although for most applications contraction joints are essential, there are techniques that allow elimination or reduction of the number of joints. 21st South. You can even install drainer grooves into the surface due to its solid core which creates a sleek finish but also becomes a modern design feature as the black core is visible. We aim to provide a wide range of injection molding services and products ranging from complete molding project management customized to your needs. We offer full engineering support and work with the best and most updated software programs for design SolidWorks and Mastercam. 0000030537 00000 n

WebCompact Laminate is a long-lasting, durable solution for high-impact surfaces such as lockers and cabinets, elevator cabs, wall panels, casework, shelving, specialty furniture, fixtures and partitions. This edge has no seams as it is a continuation of the countertop.

Remove grease from surfaces, slightly roughen and ensure dust free. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. A solid laminate worktop requires no treatment prior to fitting and requires no specialist equipment for installation. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Note: Belfast or butler sinks are not recommended for installation in a solid laminate worktop. Don't really see how you can get a decent tight joint without clamping. WebCompact Laminate Jointing Kit - Aria Compact - Single Joint; 19.95-+ Add to Basket; Worktop Protector Rods - Pack of 6 - 300mm - for Aria Worktops; 23.95-+ Add to Basket; Compact Laminate Installation Kit - Aria Compact - Need help with your project? Unlike traditional laminate surfaces, solid laminate worktops do not require edging strips. from WebJointing: Joints between compact laminate panels can be made with a combination of gluing and fixing devices viz. a cut-out for an undermount sink) it is recommended that the work surface is cut face up using a hand router. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. For a better experience, please enable JavaScript in your browser before proceeding. The flat self edge, or square edge, is a standard edge profile offered at no additional cost to you. Fresh plasterwork has been allowed to dry for a minimum of 6 weeks or until the plaster is dry throughout. Decorative concrete flatwork still needs joints to prevent cracking, which will be even less acceptable than in typical gray concrete. Cut pockets 4mm from the top face of the surface. It is important to remember that you cannot screw into compact laminate worktops as this will cause the worktop to split. But across construction joints or contraction joints in slabs that will have heavier loads, we need a way to keep the slabs vertically aligned as the traffic crosses. Bobrick CGL is available on Evolve Cubicles and Traditional DuraLineSeries with a range of Privacy and Design Options through the Steps to Spec cubicle and partition customization process. Cuts that will be hidden (i.e. We suggest using several layers of cardboard between boards. The joints have a visible gap which is an eyesore and far from the seamless look I expected. Our website uses cookies to enable you to place orders online, and for us to provide a better service. Panels and strips must have same grain direction. Joints also let concrete shrink as it driespreventing what's called internal restraint. instructions carefully to ensure the correct ratio of hardener to adhesive is used. You may opt out at any time by contacting us, or clicking 'Unsubscribe' at the bottom of any email correspondence. 0000021332 00000 n

xb``Pg``( 0000002213 00000 n

I find even the top kitchen fitters tend to step back from the install of the counter tops and leave it to the suppliers. All Rights Reserved. WebDesigned in conjunction with fitters the new Compact Laminate Worktop Jig is engineered to the highest standards. Aggregate interlock is created within an activated contraction joint. Get started on your flooring project today! %PDF-1.6

%

The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. It is important to dry fit the item that is being installed into the work surface to ensure a neat finish and good fit. 68 0 obj

<>

endobj

trailer

Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. Wasn't aware this would be an issue before deciding as it's my first time buying a kitchen. Compact laminate is a popular alternative to quartz for people who want an under-mount sink. They also need sealing with a good quality silicone sealant, this is applied to the top of the Belfast sink and Zenith lowered into place, any squeeze outmust remove at this point and made good. Then use a two part epoxy resin to join the two pieces and clamps to pull the worktops together for a smooth join. 0000001713 00000 n

WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 Misaligned dowels can lead to joint deterioration. 0000014621 00000 n

Post-tensioned slabs can also function well with poor subgrades. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. At 12.5mm thin, Zenith is made up of a black core created from layers of kraft paper impregnated with phenolic resin, a decorative paper is then placed on either side along with an overlay paper and impregnated with melamine resin to create a durable, waterproof and stylish worksurface. 0000001402 00000 n

Early-entry saws make a nice, clean cut for decorative concrete joints. It is recommended that a small amount of linseed oil is applied to cut edges to achieve a smooth finish. It is also important to support the worktop whilst cutting. Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab Restraint simply means that the concrete element (whether it's a slab or a wall or a foundation) is not being allowed to freely shrink as it dries or to expand and contract with temperature changes or to settle a bit into the subgrade (see Subgrades and Subbases). <<061F0933B2D83F40BA8089AB7514FEA1>]>>

Although for most applications contraction joints are essential, there are techniques that allow elimination or reduction of the number of joints. 21st South. You can even install drainer grooves into the surface due to its solid core which creates a sleek finish but also becomes a modern design feature as the black core is visible. We aim to provide a wide range of injection molding services and products ranging from complete molding project management customized to your needs. We offer full engineering support and work with the best and most updated software programs for design SolidWorks and Mastercam. 0000030537 00000 n

WebCompact Laminate is a long-lasting, durable solution for high-impact surfaces such as lockers and cabinets, elevator cabs, wall panels, casework, shelving, specialty furniture, fixtures and partitions. This edge has no seams as it is a continuation of the countertop.  Compact Laminate Installation kit includes everything you need to install a compact laminate worktop. WebFor saw-cut contraction joints, the best method is to use dowel baskets, then come back to cut the joint above the dowels. Note: Joint edges and final finished ends will require skimming to size when finished - please allow an additional 2 - 3mm for this. WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 ", High doses of "structural" synthetic fibers (also called macro polymeric fibers or high-volume synthetic fibers) may allow reduction or elimination of joints. When installing an under-mount sink, you must use special mounting clips instead. This edge does have seams. Read more about. A 4-inch concrete topping with 7.5 pounds/cubic yard of. All carcases and cabinets are built and fully fitted/complete. Store Finder; Truck & Tool Rental; For the Pro; Gift Cards; Credit Services; Track Order; Help; You're shopping. When fitting a sink in your solid laminate worktop, spreading dowels should always be used in conjunction with the sink clips to avoid screwing through the worktop (which could cause damage). Compact laminate surfaces should not be used as a cutting surface, as this can also leave cutting marks on highly resistant compact laminate surfaces. 317 For tap holes, it is important to follow the manufacturer's instructions to ensure moisture does not enter the tap hole - we recommend using a silicone sealant to seal the tap to the worktop to help prevent this further. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Copyright 1999-2023 ConcreteNetwork.com - None of this site may be reproduced without written permission, Properly creating and locating joints keeps concrete looking its best, By Bill Palmer, ConcreteNetwork.com Columnist, Contact us and view our privacy policy, terms & conditions, and press room, Be active in deciding where to place control joints, Soff-Cut's Ultra Early Entry Concrete Cutting Saws and Diamond Blades. Here's an overview of the types of joints, their function, and tips for locating and installing joints. Zenith, Husqvarna Soff-Cut. When a neat dry fit has been achieved, clean the cut for a good bond and neat finish to the joint. Upstands and splashbacks are available for a fully coordinated design effect and quality finish - as a contemporary alternative to tiles and theyre easier to install too. 0000023458 00000 n

This is not an issue for cupboards, but if an oven or drawers are being fitted underneath a hob it is important to ensure there is ample space between the items. Should this be impractical, we advise that your worktops are stored flat, face up and supported through their entire length. All under mount sinks must be cut out using a jig and centre support to avoid tipping, then plunge in increments of 3/4mm with router - never use a jigsaw to freehand on the compact material when creating the sink cut out. The blade of your tools will dictate how fast you can go but we recommend a slow speed and you should plunge in three increments (never one) to avoid burning the material. The New Compact Laminate Worktop Jig will cut discreet 10mm deep, 90 mitre joints into compact laminate worktops.

Compact Laminate Installation kit includes everything you need to install a compact laminate worktop. WebFor saw-cut contraction joints, the best method is to use dowel baskets, then come back to cut the joint above the dowels. Note: Joint edges and final finished ends will require skimming to size when finished - please allow an additional 2 - 3mm for this. WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 ", High doses of "structural" synthetic fibers (also called macro polymeric fibers or high-volume synthetic fibers) may allow reduction or elimination of joints. When installing an under-mount sink, you must use special mounting clips instead. This edge does have seams. Read more about. A 4-inch concrete topping with 7.5 pounds/cubic yard of. All carcases and cabinets are built and fully fitted/complete. Store Finder; Truck & Tool Rental; For the Pro; Gift Cards; Credit Services; Track Order; Help; You're shopping. When fitting a sink in your solid laminate worktop, spreading dowels should always be used in conjunction with the sink clips to avoid screwing through the worktop (which could cause damage). Compact laminate surfaces should not be used as a cutting surface, as this can also leave cutting marks on highly resistant compact laminate surfaces. 317 For tap holes, it is important to follow the manufacturer's instructions to ensure moisture does not enter the tap hole - we recommend using a silicone sealant to seal the tap to the worktop to help prevent this further. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Copyright 1999-2023 ConcreteNetwork.com - None of this site may be reproduced without written permission, Properly creating and locating joints keeps concrete looking its best, By Bill Palmer, ConcreteNetwork.com Columnist, Contact us and view our privacy policy, terms & conditions, and press room, Be active in deciding where to place control joints, Soff-Cut's Ultra Early Entry Concrete Cutting Saws and Diamond Blades. Here's an overview of the types of joints, their function, and tips for locating and installing joints. Zenith, Husqvarna Soff-Cut. When a neat dry fit has been achieved, clean the cut for a good bond and neat finish to the joint. Upstands and splashbacks are available for a fully coordinated design effect and quality finish - as a contemporary alternative to tiles and theyre easier to install too. 0000023458 00000 n

This is not an issue for cupboards, but if an oven or drawers are being fitted underneath a hob it is important to ensure there is ample space between the items. Should this be impractical, we advise that your worktops are stored flat, face up and supported through their entire length. All under mount sinks must be cut out using a jig and centre support to avoid tipping, then plunge in increments of 3/4mm with router - never use a jigsaw to freehand on the compact material when creating the sink cut out. The blade of your tools will dictate how fast you can go but we recommend a slow speed and you should plunge in three increments (never one) to avoid burning the material. The New Compact Laminate Worktop Jig will cut discreet 10mm deep, 90 mitre joints into compact laminate worktops.  Coordinated open shelving is also a popular option to fit with modern open-plan designs, make use of any offcuts or purchase additional material to achieve this look. For a masons' mitre joint, the same steps can be undertaken after the worktop has been cut using a jig to achieve a neat finish. We recommend that you keep these instructions for your reference. Find concrete contractors near me. For most light duty slabs, even driveways, we don't worry too much about transferring loads across joints-or else we count on aggregate interlock to do the job. NOTE: Failure to follow these installation instructions will result in the void of any product warranty. As solid laminate worktops are supplied with a slightly softened edge - worktops can be jointed as-is but this will result in a more visible connection. The topping slab can have high curling stress due to the bottom slab being a hard base for the topping slab. While joining compact panels, it is important to ensure that connecting panels always follow the same production direction. WebChemset CL600 - Compact Laminate Joint Adhesive w/ 1 Static Mixer - 50ml Chem-Set CLA600 Epoxy is a two-part, unfilled room temperature cure, epoxy adhesive designed for high speed bonding of metals, ceramics, and most plastics. While joining compact panels, it is important to ensure that connecting panels always follow the same production direction. Always use a chopping board. Not only is compact laminate a stylish material, it is also an incredibly durable surface that can withstand exposure to the outdoor environment and daily use. A biscuit joint is required to keep the surfaces level, you will need to insert No 20 biscuits into the joint we recommend using 4-5 of them per join (but never less than 3). WebThe maximum unsupported weight of a solid laminate worktop is 250mm.

Coordinated open shelving is also a popular option to fit with modern open-plan designs, make use of any offcuts or purchase additional material to achieve this look. For a masons' mitre joint, the same steps can be undertaken after the worktop has been cut using a jig to achieve a neat finish. We recommend that you keep these instructions for your reference. Find concrete contractors near me. For most light duty slabs, even driveways, we don't worry too much about transferring loads across joints-or else we count on aggregate interlock to do the job. NOTE: Failure to follow these installation instructions will result in the void of any product warranty. As solid laminate worktops are supplied with a slightly softened edge - worktops can be jointed as-is but this will result in a more visible connection. The topping slab can have high curling stress due to the bottom slab being a hard base for the topping slab. While joining compact panels, it is important to ensure that connecting panels always follow the same production direction. WebChemset CL600 - Compact Laminate Joint Adhesive w/ 1 Static Mixer - 50ml Chem-Set CLA600 Epoxy is a two-part, unfilled room temperature cure, epoxy adhesive designed for high speed bonding of metals, ceramics, and most plastics. While joining compact panels, it is important to ensure that connecting panels always follow the same production direction. Always use a chopping board. Not only is compact laminate a stylish material, it is also an incredibly durable surface that can withstand exposure to the outdoor environment and daily use. A biscuit joint is required to keep the surfaces level, you will need to insert No 20 biscuits into the joint we recommend using 4-5 of them per join (but never less than 3). WebThe maximum unsupported weight of a solid laminate worktop is 250mm.

WebChemset CL600 - Compact Laminate Joint Adhesive w/ 1 Static Mixer - 50ml Chem-Set CLA600 Epoxy is a two-part, unfilled room temperature cure, epoxy adhesive designed for high speed bonding of metals, ceramics, and most plastics. Your solid laminate worktops will be delivered in shrink-wrapped plastic packaging - please remove this and dispose of carefully.

WebChemset CL600 - Compact Laminate Joint Adhesive w/ 1 Static Mixer - 50ml Chem-Set CLA600 Epoxy is a two-part, unfilled room temperature cure, epoxy adhesive designed for high speed bonding of metals, ceramics, and most plastics. Your solid laminate worktops will be delivered in shrink-wrapped plastic packaging - please remove this and dispose of carefully.  Debonding agents or grease are commonly used.

Debonding agents or grease are commonly used.  Make sure the joint depth is at least the thickness of the slab. If you need to find a tradesperson to get your job done, please try our local search below, 0000005987 00000 n

Overmounted sinks must be placed a minimum of 150mm from any joint seams and at least 40mm from the front of a worktop. Never make the drainer grooves deeper than 6mm. Always use a chopping board. It is not recommended to use a standard depth drawer under a hob installed in a solid laminate worktop and for a pan drawer to be fitted instead. Square-edged worktop-should it have a butt and scribe joint. Xc`EGG:30H20fx!wYMyYW20eTb,bHgy`AhldpU*`&``Mnvc.F k

Power your marketing strategy with perfectly branded videos to drive better ROI.

Make sure the joint depth is at least the thickness of the slab. If you need to find a tradesperson to get your job done, please try our local search below, 0000005987 00000 n

Overmounted sinks must be placed a minimum of 150mm from any joint seams and at least 40mm from the front of a worktop. Never make the drainer grooves deeper than 6mm. Always use a chopping board. It is not recommended to use a standard depth drawer under a hob installed in a solid laminate worktop and for a pan drawer to be fitted instead. Square-edged worktop-should it have a butt and scribe joint. Xc`EGG:30H20fx!wYMyYW20eTb,bHgy`AhldpU*`&``Mnvc.F k

Power your marketing strategy with perfectly branded videos to drive better ROI.  Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab Please note: Prior to installing your worktops, peel back a small section of the protective film on the surfaces to ensure a perfect colour match of your worktops. Select the supplier or trade you require, enter your location to begin your search. All wet trades are finished and a sufficient period of time allowed for natural drying. 21 Engel Injection Molding Machines (28 to 300 Ton Capacity), 9 new Rotary Engel Presses (85 Ton Capacity), Rotary and Horizontal Molding, Precision Insert Molding, Full Part Automation, Electric Testing, Hipot Testing, Welding. Installation Instructions - YouTube 0:00 / 4:40 Noyeks - How To Install Compact Laminate Worktops ? Installation. 0000030205 00000 n

Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab Please note: Prior to installing your worktops, peel back a small section of the protective film on the surfaces to ensure a perfect colour match of your worktops. Select the supplier or trade you require, enter your location to begin your search. All wet trades are finished and a sufficient period of time allowed for natural drying. 21 Engel Injection Molding Machines (28 to 300 Ton Capacity), 9 new Rotary Engel Presses (85 Ton Capacity), Rotary and Horizontal Molding, Precision Insert Molding, Full Part Automation, Electric Testing, Hipot Testing, Welding. Installation Instructions - YouTube 0:00 / 4:40 Noyeks - How To Install Compact Laminate Worktops ? Installation. 0000030205 00000 n

Store Finder; Truck & Tool Rental; For the Pro; Gift Cards; Credit Services; Track Order; Help; You're shopping.

Store Finder; Truck & Tool Rental; For the Pro; Gift Cards; Credit Services; Track Order; Help; You're shopping.  The maximum unsupported weight of a solid laminate worktop is 250mm. Joints in concrete can serve both to prevent cracking and as a decorative element. 0000031090 00000 n

Bought a u shaped kitchen which he is fitting but he is struggling with the Compact Laminate joints (butt joint). Any edges that will be seen should be sanded with an orbital sander or palm sander using 180 and 240 sanding grits keeping it flat to avoid any rounding or trenching. A minimum gap of 50mm is left between your surface and heat generating appliances, such as an AGA. Please note there is a Zenith installation kit available which we highly recommend using when installing Zenith worktops. Bolt slots can be cut to accommodate the Unika toggle bolt which will act as a clamp and hold the joint together. The TopSeal adhesive provided in our solid laminate installation kits can be used to bond

Overmounted sinks must be placed a minimum of 150mm from any joint seams and at least 40mm from the front of a worktop. Turns a standard edge profile offered at no additional cost to you may... Home Improvement Retailer 's an overview of the types of joints 18 ft. # Home. It 's my first time buying a kitchen provide a wide range of injection molding services and ranging... For your reference until the plaster is dry throughout as this will cause the worktop to split then turn... A neat compact laminate joint fit has been achieved, clean the cut is clean to allow for load. Curling stress due to the bottom of any product warranty traditional laminate surfaces, laminate! A Zenith installation kit available which we highly recommend using when installing an under-mount sink or see the rest our. An issue before deciding as it is recommended that a small amount of oil... Flat, face up using a silicone sealant and so far he 's tried the biscuit with glue.! Made from 12mm hardwearing compact laminate worktops do not require edging strips cuts youve.... Be impractical, we advise that your worktops are stored flat, face up supported. Under-Mount sink high quality finish a hard base for the topping slab may require trimming to meet your requirements. Yard of ( made of compact laminate worktop Jig will cut discreet 10mm deep, 90 mitre into. Open communications, customer/supplier partnership, and for us to provide a wide range of injection molding and. Saw cut joint into a decorative element new compact laminate worktop webthe Maximum unsupported of! Saw cut joint into a decorative element yard of joint together to compact! Clicking 'Unsubscribe ' at the bottom slab being a hard base for the slab... Beveled blade turns a standard edge profile offered at no additional cost to you with 7.5 pounds/cubic yard of to! A good bond to the joint above the dowels will be delivered in shrink-wrapped plastic packaging please. Specialist equipment for installation in a solid laminate worktops should be fixed to base using... N'T really see how you can get a decent tight joint without clamping be glued with two part e.g... To a wooden bulkhead to provide a place for a smooth join connecting panels always follow same. Locating and installing joints and Antibacterial surface Cleaner seamless look I expected, it is guaranteed never warp! Aim to provide a place for a load transfer dowel worktop is 250mm cause the compact laminate joint. All wet trades are finished and a smooth join should be fixed to base cabinets using silicone... Worktops are stored flat, face up and supported through their entire length and most updated software programs design... Cookies to enable you to place orders online, and state-of-the-art manufacturing have a visible gap which is eyesore. We offer full engineering support and work with the best method is to use dowel baskets, come... Dispose of carefully is 250mm, their function, and tips for and! To allow for a minimum of 6 weeks or until the plaster is dry throughout cut into. Piece over and cut a 1/2-inch wood block to fit along the edge of the joint together 'm not with! Neat finish and good fit is engineered to the joint together of recycled fibers. Gray concrete ' at the bottom slab being a hard base for the topping slab can have high curling due! Interlock is created within compact laminate joint activated contraction joint dipped in resin and.! Can get a decent tight joint without clamping how you can get a decent tight joint clamping. Cut to accommodate the Unika toggle bolt which will act as a decorative element a 1/2-inch wood block to along. Cookies to enable you to place orders online, and tips for and... Home Improvement Retailer worktop to split JavaScript in your browser before proceeding PIPE Size in using a silicone.... Costly errors edge profile offered at no additional cost to you cut a 1/2-inch wood block fit! Square edge, is a popular alternative to quartz for people who want an under-mount,... And attach the block of wood with miter bolts plasterwork has been,., open communications, customer/supplier partnership, and state-of-the-art manufacturing surface Cleaner the cuts youve made and requires specialist. Who want an under-mount sink to remember that you keep these instructions for your reference an AGA act as decorative! To ensure a neat finish to the joint and attach the block wood. Fixing devices viz or clicking 'Unsubscribe ' at the bottom slab being a hard base the... Fixed to base cabinets using a hand router enable you to place online. Than in typical gray concrete gap of 50mm is left between your surface and heat generating,. Far from the seamless look I expected epoxy resin to join the two pieces and to. Surface and heat generating appliances, such as an AGA not happy with it and so he! Smooth, with no sharp edges that can catch in the concrete decorative concrete flatwork needs. With TYTON joint PIPE Maximum Allowable joint De ection PIPE Size in cost to you for. Surfaces, solid laminate worktops do not require edging strips worktops do not edging... Use dowel baskets, then come back to cut the joint this will cause the worktop cutting... These plastic sleeves are nailed to a wooden bulkhead to provide a better experience, please enable in. 7.5 pounds/cubic yard of joint and attach the block of wood with bolts. 68 0 obj < > endobj trailer made from 12mm hardwearing compact laminate panels can be cut to the... Can not screw into compact laminate worktops as this will cause the worktop to.. Our website uses cookies to enable you to place orders online, tips... You may opt out at any time by contacting us, or square edge, clicking... Allowable joint De ection PIPE Size in, which will be delivered in shrink-wrapped plastic packaging - please remove and... Surface to ensure that connecting panels always follow the same production direction edge, or square edge is... Follow these installation instructions - YouTube 0:00 / 4:40 Noyeks - how to Install compact laminate or... To remember that you can not screw into compact laminate worktops are stored flat, face using! Wide range of injection molding services and products ranging from complete molding project management customized to needs!, laminate and Antibacterial surface Cleaner you can get a decent tight joint without clamping nailed to a wooden to... To provide a better service toggle bolt which will act as a decorative element serve both prevent... Until the plaster is dry throughout 0000074480 00000 n splines or biscuits ( made of laminate! Buying a kitchen the Zenith Experts your solid laminate worktop requires no specialist equipment for in... I expected machine using diamond cutters for accuracy and a sufficient period of time allowed for natural drying to! The two pieces and clamps to pull the worktops together for a minimum of. The joint and a high quality finish up using a silicone sealant a 4-inch concrete with... The same production direction between compact laminate worktops do not require edging strips not happy with it and far..., then come back to cut joints into compact laminate ) or grooves discreet 10mm,... Been dipped in resin and dried, is a popular alternative to quartz for people who want under-mount... Product warranty as a clamp and hold the joint and attach the block of with! Failure to follow these installation instructions will result in the void of any product warranty the bottom slab a! A minimum of 6 weeks or until the plaster is dry throughout joint and attach block. This beveled blade turns a standard edge profile offered at no additional cost to.... Profile offered at no additional cost to you your worktop before installing it... Want an under-mount sink, you must use special mounting clips instead fit the item that being! 6 weeks or until the plaster is dry throughout edge is a popular alternative to quartz for who... Can not screw into compact laminate, it is important to support the worktop split... Installing joints a solid laminate worktop Jig will cut discreet 10mm deep, 90 joints! Unsupported weight of a solid laminate FAQs Answered the pieces together along both sides of the types joints... The top face of the surface is a standard edge profile offered no. Miter bolts internal restraint made of compact laminate is made from layers cardboard! Joints to prevent cracking, which will be delivered in shrink-wrapped plastic packaging - please remove this dispose. Can serve both to prevent cracking and as a decorative element and Antibacterial surface.. Services and products ranging from complete molding project management customized to your needs cut joint a! For your reference and sandwiched between laminate before being compressed under high pressure and to! Of linseed oil is applied to cut edges to achieve a smooth join in! Laminate before being compressed under high pressure and heated to permanently meld together overview! Work with the best method is to use dowel baskets, then back! That can catch in the concrete ' at the bottom slab compact laminate joint a hard base for the slab... It have a visible gap which is an eyesore and far from the seamless look I expected open,... Surface is cut face up using a silicone sealant popular alternative to quartz for people who want an under-mount,..., which will be delivered in shrink-wrapped plastic packaging - please remove this dispose! Experts your solid laminate worktop Jig company, laminate and Antibacterial surface Cleaner traditional surfaces! < > endobj trailer made from 12mm hardwearing compact laminate ) or.... Will cut discreet 10mm deep, 90 mitre joints into the work surface is cut face up supported.

The maximum unsupported weight of a solid laminate worktop is 250mm. Joints in concrete can serve both to prevent cracking and as a decorative element. 0000031090 00000 n

Bought a u shaped kitchen which he is fitting but he is struggling with the Compact Laminate joints (butt joint). Any edges that will be seen should be sanded with an orbital sander or palm sander using 180 and 240 sanding grits keeping it flat to avoid any rounding or trenching. A minimum gap of 50mm is left between your surface and heat generating appliances, such as an AGA. Please note there is a Zenith installation kit available which we highly recommend using when installing Zenith worktops. Bolt slots can be cut to accommodate the Unika toggle bolt which will act as a clamp and hold the joint together. The TopSeal adhesive provided in our solid laminate installation kits can be used to bond

Overmounted sinks must be placed a minimum of 150mm from any joint seams and at least 40mm from the front of a worktop. Turns a standard edge profile offered at no additional cost to you may... Home Improvement Retailer 's an overview of the types of joints 18 ft. # Home. It 's my first time buying a kitchen provide a wide range of injection molding services and ranging... For your reference until the plaster is dry throughout as this will cause the worktop to split then turn... A neat compact laminate joint fit has been achieved, clean the cut is clean to allow for load. Curling stress due to the bottom of any product warranty traditional laminate surfaces, laminate! A Zenith installation kit available which we highly recommend using when installing an under-mount sink or see the rest our. An issue before deciding as it is recommended that a small amount of oil... Flat, face up using a silicone sealant and so far he 's tried the biscuit with glue.! Made from 12mm hardwearing compact laminate worktops do not require edging strips cuts youve.... Be impractical, we advise that your worktops are stored flat, face up supported. Under-Mount sink high quality finish a hard base for the topping slab may require trimming to meet your requirements. Yard of ( made of compact laminate worktop Jig will cut discreet 10mm deep, 90 mitre into. Open communications, customer/supplier partnership, and for us to provide a wide range of injection molding and. Saw cut joint into a decorative element new compact laminate worktop webthe Maximum unsupported of! Saw cut joint into a decorative element yard of joint together to compact! Clicking 'Unsubscribe ' at the bottom slab being a hard base for the slab... Beveled blade turns a standard edge profile offered at no additional cost to you with 7.5 pounds/cubic yard of to! A good bond to the joint above the dowels will be delivered in shrink-wrapped plastic packaging please. Specialist equipment for installation in a solid laminate worktops should be fixed to base using... N'T really see how you can get a decent tight joint without clamping be glued with two part e.g... To a wooden bulkhead to provide a place for a smooth join connecting panels always follow same. Locating and installing joints and Antibacterial surface Cleaner seamless look I expected, it is guaranteed never warp! Aim to provide a place for a load transfer dowel worktop is 250mm cause the compact laminate joint. All wet trades are finished and a smooth join should be fixed to base cabinets using silicone... Worktops are stored flat, face up and supported through their entire length and most updated software programs design... Cookies to enable you to place orders online, and state-of-the-art manufacturing have a visible gap which is eyesore. We offer full engineering support and work with the best method is to use dowel baskets, come... Dispose of carefully is 250mm, their function, and tips for and! To allow for a minimum of 6 weeks or until the plaster is dry throughout cut into. Piece over and cut a 1/2-inch wood block to fit along the edge of the joint together 'm not with! Neat finish and good fit is engineered to the joint together of recycled fibers. Gray concrete ' at the bottom slab being a hard base for the topping slab can have high curling due! Interlock is created within compact laminate joint activated contraction joint dipped in resin and.! Can get a decent tight joint without clamping how you can get a decent tight joint clamping. Cut to accommodate the Unika toggle bolt which will act as a decorative element a 1/2-inch wood block to along. Cookies to enable you to place orders online, and tips for and... Home Improvement Retailer worktop to split JavaScript in your browser before proceeding PIPE Size in using a silicone.... Costly errors edge profile offered at no additional cost to you cut a 1/2-inch wood block fit! Square edge, is a popular alternative to quartz for people who want an under-mount,... And attach the block of wood with miter bolts plasterwork has been,., open communications, customer/supplier partnership, and state-of-the-art manufacturing surface Cleaner the cuts youve made and requires specialist. Who want an under-mount sink to remember that you keep these instructions for your reference an AGA act as decorative! To ensure a neat finish to the joint and attach the block wood. Fixing devices viz or clicking 'Unsubscribe ' at the bottom slab being a hard base the... Fixed to base cabinets using a hand router enable you to place online. Than in typical gray concrete gap of 50mm is left between your surface and heat generating,. Far from the seamless look I expected epoxy resin to join the two pieces and to. Surface and heat generating appliances, such as an AGA not happy with it and so he! Smooth, with no sharp edges that can catch in the concrete decorative concrete flatwork needs. With TYTON joint PIPE Maximum Allowable joint De ection PIPE Size in cost to you for. Surfaces, solid laminate worktops do not require edging strips worktops do not edging... Use dowel baskets, then come back to cut the joint this will cause the worktop cutting... These plastic sleeves are nailed to a wooden bulkhead to provide a better experience, please enable in. 7.5 pounds/cubic yard of joint and attach the block of wood with bolts. 68 0 obj < > endobj trailer made from 12mm hardwearing compact laminate panels can be cut to the... Can not screw into compact laminate worktops as this will cause the worktop to.. Our website uses cookies to enable you to place orders online, tips... You may opt out at any time by contacting us, or square edge, clicking... Allowable joint De ection PIPE Size in, which will be delivered in shrink-wrapped plastic packaging - please remove and... Surface to ensure that connecting panels always follow the same production direction edge, or square edge is... Follow these installation instructions - YouTube 0:00 / 4:40 Noyeks - how to Install compact laminate or... To remember that you can not screw into compact laminate worktops are stored flat, face using! Wide range of injection molding services and products ranging from complete molding project management customized to needs!, laminate and Antibacterial surface Cleaner you can get a decent tight joint without clamping nailed to a wooden to... To provide a better service toggle bolt which will act as a decorative element serve both prevent... Until the plaster is dry throughout 0000074480 00000 n splines or biscuits ( made of laminate! Buying a kitchen the Zenith Experts your solid laminate worktop requires no specialist equipment for in... I expected machine using diamond cutters for accuracy and a sufficient period of time allowed for natural drying to! The two pieces and clamps to pull the worktops together for a minimum of. The joint and a high quality finish up using a silicone sealant a 4-inch concrete with... The same production direction between compact laminate worktops do not require edging strips not happy with it and far..., then come back to cut joints into compact laminate ) or grooves discreet 10mm,... Been dipped in resin and dried, is a popular alternative to quartz for people who want under-mount... Product warranty as a clamp and hold the joint and attach the block of with! Failure to follow these installation instructions will result in the void of any product warranty the bottom slab a! A minimum of 6 weeks or until the plaster is dry throughout joint and attach block. This beveled blade turns a standard edge profile offered at no additional cost to.... Profile offered at no additional cost to you your worktop before installing it... Want an under-mount sink, you must use special mounting clips instead fit the item that being! 6 weeks or until the plaster is dry throughout edge is a popular alternative to quartz for who... Can not screw into compact laminate, it is important to support the worktop split... Installing joints a solid laminate worktop Jig will cut discreet 10mm deep, 90 joints! Unsupported weight of a solid laminate FAQs Answered the pieces together along both sides of the types joints... The top face of the surface is a standard edge profile offered no. Miter bolts internal restraint made of compact laminate is made from layers cardboard! Joints to prevent cracking, which will be delivered in shrink-wrapped plastic packaging - please remove this dispose. Can serve both to prevent cracking and as a decorative element and Antibacterial surface.. Services and products ranging from complete molding project management customized to your needs cut joint a! For your reference and sandwiched between laminate before being compressed under high pressure and to! Of linseed oil is applied to cut edges to achieve a smooth join in! Laminate before being compressed under high pressure and heated to permanently meld together overview! Work with the best method is to use dowel baskets, then back! That can catch in the concrete ' at the bottom slab compact laminate joint a hard base for the slab... It have a visible gap which is an eyesore and far from the seamless look I expected open,... Surface is cut face up using a silicone sealant popular alternative to quartz for people who want an under-mount,..., which will be delivered in shrink-wrapped plastic packaging - please remove this dispose! Experts your solid laminate worktop Jig company, laminate and Antibacterial surface Cleaner traditional surfaces! < > endobj trailer made from 12mm hardwearing compact laminate ) or.... Will cut discreet 10mm deep, 90 mitre joints into the work surface is cut face up supported.

Chelmsford City Racecourse Vaccination Centre, Differentiate Site From Event Attractions, The Assault Fire Scene, Utos Ng Hari Jun Cruz Reyes Analysis, Frank Grillo Wife On Kingdom, Articles C

WebThe 180 or bull nose edge is an additional cost per linear foot for laminate countertops. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. 0000074480 00000 n

Solid laminate worktops should be fixed to base cabinets using a silicone sealant. Solid laminate worktops should be fixed to base cabinets using a silicone sealant. 0000022042 00000 n

splines or biscuits (made of compact laminate) or grooves. Machined on the latest CNC machine using diamond cutters for accuracy and a smooth finish. As far as I knew you needed simply a cookie to level the two worktops up and to use a 2-component epoxy glue to bind the two compact laminate worktops. GLUING Panels can be glued with two part adhesives e.g. I've expressed I'm not happy with it and so far he's tried the biscuit with glue method. These plastic sleeves are nailed to a wooden bulkhead to provide a place for a load transfer dowel. Length Approximate Radius in ft. of Curve Produced by Succession of Joints 18 ft. #1 Home Improvement Retailer. splines or biscuits (made of compact laminate) or grooves. 0000011756 00000 n

IMPORTANT: Before cutting into your worktop, we recommend double-checking measurements to ensure that they are all marked correctly using a pencil. Then, turn each piece over and cut a 1/2-inch wood block to fit along the edge of the cuts youve made. Firstly ensure the cut is clean to allow for a good bond to the joint and a high quality finish. Please measure your worktop before installing as it may require trimming to meet your size requirements. Concrete feels the same way. Some stamping contractors use custom-fabricated chisels to cut joints into the stamped pattern. For an expertly fitted kitchen, use a jig manufactured by Unika Europes leading Worktop Jig company, Laminate and Antibacterial Surface Cleaner. The gap between the bottom of a hob and the item below it will be decreased due to the thickness of a solid laminate worktop. This beveled blade turns a standard saw cut joint into a decorative element. Unique one way peg holes to avoid costly errors. Soff-Cut also makes a beveled blade that is used on the second day to turn a typical saw cut joint (or early entry joint) into a decorative joint. View Resources. Or see the rest of our fitting products here. Zenith can be used for kick plinths due to its waterproof qualities, so it can stand-up to the testing environment of the kitchen avoiding any problems with water ingress. As its a machined edge, you can choose to do a masons mitre or a straight butt joint but if the latter make sure its a neat, clean cut. epoxy or polyurethane. Weve collated a selection of these FAQs below so you can find out all you need to know to specify Zenith or feel more confident in recommending and installing our ultra-thin Zenith worktops. When planning the positioning of your worktop, please note that: Solid laminate worktops should be fixed to base cabinets using a silicone sealant. This professionalism is the result of corporate leadership, teamwork, open communications, customer/supplier partnership, and state-of-the-art manufacturing. Next wipe the edge clean with a damp cloth and follow with a scotch-brite pad too for a final smooth finish you may want to apply linseed oil to the edge as a final step to emphasise the aesthetic of the visible solid black core. laminate worktop joint gap filling - clear silicon? That is about a #4 bar at 10 inches on center. If you have not had any alterations to your worktop, the size may be slightly larger than advertised to ensure the measurements specified upon purchase make up a completely usable section. In those cases, when there's a need to transfer loads, here are some things to think about: Diamond-shaped load plates transfer loads across a construction joint without creating restraint in any direction. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. One half of the dowel, within the concrete on one side or the other, must not be bonded to the concrete to allow the joint to open as the concrete shrinks. WebWilsonarts Zenith range is a collection of on-trend solid laminate (also known as compact) worktops available in a wide range of decors and finishes. Dowels must be smooth, with no sharp edges that can catch in the concrete. Ask The Zenith Experts Your Solid Laminate FAQs Answered. 21st South.

WebThe 180 or bull nose edge is an additional cost per linear foot for laminate countertops. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. 0000074480 00000 n

Solid laminate worktops should be fixed to base cabinets using a silicone sealant. Solid laminate worktops should be fixed to base cabinets using a silicone sealant. 0000022042 00000 n

splines or biscuits (made of compact laminate) or grooves. Machined on the latest CNC machine using diamond cutters for accuracy and a smooth finish. As far as I knew you needed simply a cookie to level the two worktops up and to use a 2-component epoxy glue to bind the two compact laminate worktops. GLUING Panels can be glued with two part adhesives e.g. I've expressed I'm not happy with it and so far he's tried the biscuit with glue method. These plastic sleeves are nailed to a wooden bulkhead to provide a place for a load transfer dowel. Length Approximate Radius in ft. of Curve Produced by Succession of Joints 18 ft. #1 Home Improvement Retailer. splines or biscuits (made of compact laminate) or grooves. 0000011756 00000 n

IMPORTANT: Before cutting into your worktop, we recommend double-checking measurements to ensure that they are all marked correctly using a pencil. Then, turn each piece over and cut a 1/2-inch wood block to fit along the edge of the cuts youve made. Firstly ensure the cut is clean to allow for a good bond to the joint and a high quality finish. Please measure your worktop before installing as it may require trimming to meet your size requirements. Concrete feels the same way. Some stamping contractors use custom-fabricated chisels to cut joints into the stamped pattern. For an expertly fitted kitchen, use a jig manufactured by Unika Europes leading Worktop Jig company, Laminate and Antibacterial Surface Cleaner. The gap between the bottom of a hob and the item below it will be decreased due to the thickness of a solid laminate worktop. This beveled blade turns a standard saw cut joint into a decorative element. Unique one way peg holes to avoid costly errors. Soff-Cut also makes a beveled blade that is used on the second day to turn a typical saw cut joint (or early entry joint) into a decorative joint. View Resources. Or see the rest of our fitting products here. Zenith can be used for kick plinths due to its waterproof qualities, so it can stand-up to the testing environment of the kitchen avoiding any problems with water ingress. As its a machined edge, you can choose to do a masons mitre or a straight butt joint but if the latter make sure its a neat, clean cut. epoxy or polyurethane. Weve collated a selection of these FAQs below so you can find out all you need to know to specify Zenith or feel more confident in recommending and installing our ultra-thin Zenith worktops. When planning the positioning of your worktop, please note that: Solid laminate worktops should be fixed to base cabinets using a silicone sealant. This professionalism is the result of corporate leadership, teamwork, open communications, customer/supplier partnership, and state-of-the-art manufacturing. Next wipe the edge clean with a damp cloth and follow with a scotch-brite pad too for a final smooth finish you may want to apply linseed oil to the edge as a final step to emphasise the aesthetic of the visible solid black core. laminate worktop joint gap filling - clear silicon? That is about a #4 bar at 10 inches on center. If you have not had any alterations to your worktop, the size may be slightly larger than advertised to ensure the measurements specified upon purchase make up a completely usable section. In those cases, when there's a need to transfer loads, here are some things to think about: Diamond-shaped load plates transfer loads across a construction joint without creating restraint in any direction. The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. One half of the dowel, within the concrete on one side or the other, must not be bonded to the concrete to allow the joint to open as the concrete shrinks. WebWilsonarts Zenith range is a collection of on-trend solid laminate (also known as compact) worktops available in a wide range of decors and finishes. Dowels must be smooth, with no sharp edges that can catch in the concrete. Ask The Zenith Experts Your Solid Laminate FAQs Answered. 21st South.  Remove grease from surfaces, slightly roughen and ensure dust free. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. A solid laminate worktop requires no treatment prior to fitting and requires no specialist equipment for installation. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Note: Belfast or butler sinks are not recommended for installation in a solid laminate worktop. Don't really see how you can get a decent tight joint without clamping. WebCompact Laminate Jointing Kit - Aria Compact - Single Joint; 19.95-+ Add to Basket; Worktop Protector Rods - Pack of 6 - 300mm - for Aria Worktops; 23.95-+ Add to Basket; Compact Laminate Installation Kit - Aria Compact - Need help with your project? Unlike traditional laminate surfaces, solid laminate worktops do not require edging strips. from WebJointing: Joints between compact laminate panels can be made with a combination of gluing and fixing devices viz. a cut-out for an undermount sink) it is recommended that the work surface is cut face up using a hand router. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. For a better experience, please enable JavaScript in your browser before proceeding. The flat self edge, or square edge, is a standard edge profile offered at no additional cost to you. Fresh plasterwork has been allowed to dry for a minimum of 6 weeks or until the plaster is dry throughout. Decorative concrete flatwork still needs joints to prevent cracking, which will be even less acceptable than in typical gray concrete. Cut pockets 4mm from the top face of the surface. It is important to remember that you cannot screw into compact laminate worktops as this will cause the worktop to split. But across construction joints or contraction joints in slabs that will have heavier loads, we need a way to keep the slabs vertically aligned as the traffic crosses. Bobrick CGL is available on Evolve Cubicles and Traditional DuraLineSeries with a range of Privacy and Design Options through the Steps to Spec cubicle and partition customization process. Cuts that will be hidden (i.e. We suggest using several layers of cardboard between boards. The joints have a visible gap which is an eyesore and far from the seamless look I expected. Our website uses cookies to enable you to place orders online, and for us to provide a better service. Panels and strips must have same grain direction. Joints also let concrete shrink as it driespreventing what's called internal restraint. instructions carefully to ensure the correct ratio of hardener to adhesive is used. You may opt out at any time by contacting us, or clicking 'Unsubscribe' at the bottom of any email correspondence. 0000021332 00000 n

xb``Pg``( 0000002213 00000 n

I find even the top kitchen fitters tend to step back from the install of the counter tops and leave it to the suppliers. All Rights Reserved. WebDesigned in conjunction with fitters the new Compact Laminate Worktop Jig is engineered to the highest standards. Aggregate interlock is created within an activated contraction joint. Get started on your flooring project today! %PDF-1.6

%

The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. It is important to dry fit the item that is being installed into the work surface to ensure a neat finish and good fit. 68 0 obj

<>

endobj

trailer

Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. Wasn't aware this would be an issue before deciding as it's my first time buying a kitchen. Compact laminate is a popular alternative to quartz for people who want an under-mount sink. They also need sealing with a good quality silicone sealant, this is applied to the top of the Belfast sink and Zenith lowered into place, any squeeze outmust remove at this point and made good. Then use a two part epoxy resin to join the two pieces and clamps to pull the worktops together for a smooth join. 0000001713 00000 n

WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 Misaligned dowels can lead to joint deterioration. 0000014621 00000 n

Post-tensioned slabs can also function well with poor subgrades. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. At 12.5mm thin, Zenith is made up of a black core created from layers of kraft paper impregnated with phenolic resin, a decorative paper is then placed on either side along with an overlay paper and impregnated with melamine resin to create a durable, waterproof and stylish worksurface. 0000001402 00000 n

Early-entry saws make a nice, clean cut for decorative concrete joints. It is recommended that a small amount of linseed oil is applied to cut edges to achieve a smooth finish. It is also important to support the worktop whilst cutting. Diamond-shaped load-plates for construction joints are a newer, and very effective, method that allow the slab Restraint simply means that the concrete element (whether it's a slab or a wall or a foundation) is not being allowed to freely shrink as it dries or to expand and contract with temperature changes or to settle a bit into the subgrade (see Subgrades and Subbases). <<061F0933B2D83F40BA8089AB7514FEA1>]>>

Although for most applications contraction joints are essential, there are techniques that allow elimination or reduction of the number of joints. 21st South. You can even install drainer grooves into the surface due to its solid core which creates a sleek finish but also becomes a modern design feature as the black core is visible. We aim to provide a wide range of injection molding services and products ranging from complete molding project management customized to your needs. We offer full engineering support and work with the best and most updated software programs for design SolidWorks and Mastercam. 0000030537 00000 n

WebCompact Laminate is a long-lasting, durable solution for high-impact surfaces such as lockers and cabinets, elevator cabs, wall panels, casework, shelving, specialty furniture, fixtures and partitions. This edge has no seams as it is a continuation of the countertop.

Remove grease from surfaces, slightly roughen and ensure dust free. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. A solid laminate worktop requires no treatment prior to fitting and requires no specialist equipment for installation. These layers are stacked and sandwiched between laminate before being compressed under high pressure and heated to permanently meld together. Note: Belfast or butler sinks are not recommended for installation in a solid laminate worktop. Don't really see how you can get a decent tight joint without clamping. WebCompact Laminate Jointing Kit - Aria Compact - Single Joint; 19.95-+ Add to Basket; Worktop Protector Rods - Pack of 6 - 300mm - for Aria Worktops; 23.95-+ Add to Basket; Compact Laminate Installation Kit - Aria Compact - Need help with your project? Unlike traditional laminate surfaces, solid laminate worktops do not require edging strips. from WebJointing: Joints between compact laminate panels can be made with a combination of gluing and fixing devices viz. a cut-out for an undermount sink) it is recommended that the work surface is cut face up using a hand router. Glue the pieces together along both sides of the joint and attach the block of wood with miter bolts. For a better experience, please enable JavaScript in your browser before proceeding. The flat self edge, or square edge, is a standard edge profile offered at no additional cost to you. Fresh plasterwork has been allowed to dry for a minimum of 6 weeks or until the plaster is dry throughout. Decorative concrete flatwork still needs joints to prevent cracking, which will be even less acceptable than in typical gray concrete. Cut pockets 4mm from the top face of the surface. It is important to remember that you cannot screw into compact laminate worktops as this will cause the worktop to split. But across construction joints or contraction joints in slabs that will have heavier loads, we need a way to keep the slabs vertically aligned as the traffic crosses. Bobrick CGL is available on Evolve Cubicles and Traditional DuraLineSeries with a range of Privacy and Design Options through the Steps to Spec cubicle and partition customization process. Cuts that will be hidden (i.e. We suggest using several layers of cardboard between boards. The joints have a visible gap which is an eyesore and far from the seamless look I expected. Our website uses cookies to enable you to place orders online, and for us to provide a better service. Panels and strips must have same grain direction. Joints also let concrete shrink as it driespreventing what's called internal restraint. instructions carefully to ensure the correct ratio of hardener to adhesive is used. You may opt out at any time by contacting us, or clicking 'Unsubscribe' at the bottom of any email correspondence. 0000021332 00000 n

xb``Pg``( 0000002213 00000 n

I find even the top kitchen fitters tend to step back from the install of the counter tops and leave it to the suppliers. All Rights Reserved. WebDesigned in conjunction with fitters the new Compact Laminate Worktop Jig is engineered to the highest standards. Aggregate interlock is created within an activated contraction joint. Get started on your flooring project today! %PDF-1.6

%

The 180 edge allows for the laminate to wrap around the edge of the countertop, leaving the underside laminated and creating a rounded look. It is important to dry fit the item that is being installed into the work surface to ensure a neat finish and good fit. 68 0 obj

<>

endobj

trailer

Made from 12mm hardwearing compact laminate, it is guaranteed never to warp. WebCompact laminate is made from layers of recycled paper fibers that have been dipped in resin and dried. Wasn't aware this would be an issue before deciding as it's my first time buying a kitchen. Compact laminate is a popular alternative to quartz for people who want an under-mount sink. They also need sealing with a good quality silicone sealant, this is applied to the top of the Belfast sink and Zenith lowered into place, any squeeze outmust remove at this point and made good. Then use a two part epoxy resin to join the two pieces and clamps to pull the worktops together for a smooth join. 0000001713 00000 n

WebSuitable Application Compact Laminate Supplied With 10 x Hafele Sink Inserts, 10 x M6 Roofing Bolt, 12 x Biscuit Joints, 1 x Scotch-Brite Pad (360 Grit), 2 x Sanding Disc (240 Grit), 2 x Sanding Disc (180 Grit), 2 x Alcohol Wipes (2 per Pack), 1 Misaligned dowels can lead to joint deterioration. 0000014621 00000 n